Tel: +86-13817790968

Email: [email protected]

Tel: +86-13817790968

Email: [email protected]

If you have ever touched a magnet you must have wondered, how it works? There are magnets of all different shapes and sizes, and they are all fascinating! Alnico magnets are a type of magnet that we will cover. This essay teaches you all about alnico things… We will be diving into how sturdy they are, what kinds of materials make them up, where they are used in everyday life as well how to have that cared for to last a long time. Given this much needed uplift which every good soul requires.

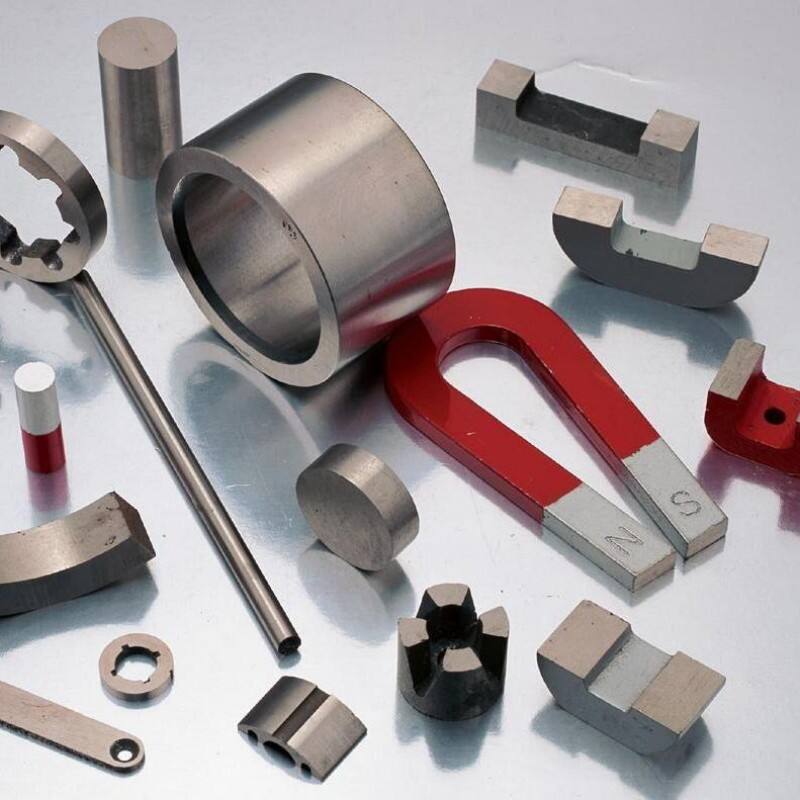

These are the small disc magnets, and they combine special metals to add power. The list includes iron, aluminum, nickel and cobalt. Occasionally, other metals (copper and titanium) are also added to improve the benefits of these materials. This enslaved inward their melting victimisation a excessively hot furnace and histrion the line of alnico. Those shapes melts and then it sits in a mold and then cooled to get them hard! This is the process that makes alnico magnets so unique.

The steel and magnets are powerful magnets. They attach to other metal things quite easily and are well proofed against being demagnetized. This means they can generate strong magnetic fields for a long time without losing their magnetism such that each other magnets and metal objects attracted to it. Due to this fact is why small disc magnets are so commonly used, it makes them a vital material in variety of devices and implements which are used on today.

Alnico magnets may be found in a variety of everyday machines and tools that we see or use. They are used extensively in motors, speakers, and sensors for devices working at their best. Alincio magnets are used in medical machines, such as MRI scanners to help doctors look inside our bodies. Another merit that makes alnico bar magnets more attractive to use is; they can operate at extreme temperatures, up to 900°C! Which is actually quite remarkable and makes them useful in a wide range of environments.

In a variety of fields and industries, numerous alnico magnets are applied with distinct applications. As a hypothetical scenario, what would be in the automotive industry, optimized for cars, alnico magnets to keep engines rolling with optimal smoothness as well as part of the power steering? These magnets are useful in the aerospace industry which includes air plane and space travel where they used for navigation aids alo}ng with communication systems. One of the features that makes alnico magnets popular are their constant nature. They are therefore highly dependable, functioning well even after multiple years of usage.

Alnico magnets are old, being around for more than 80 years, and may have a changed lot in how they are made. In the past, they used to be produced by melting metal and then shaping it. Today, there are more modern ways of making alnico magnets such as bonding and injection molding. Research is also exploring new materials to increase the already high magnet strength and other properties of alnico. Well, that means alnico magnets just have a lot of growth and improvements being done all the time.

As with any other polished entity, alnico magnets must be looked after to retain working condition. Follow these simple steps to maintain your alnico magnets: